1. Isishwankathelo

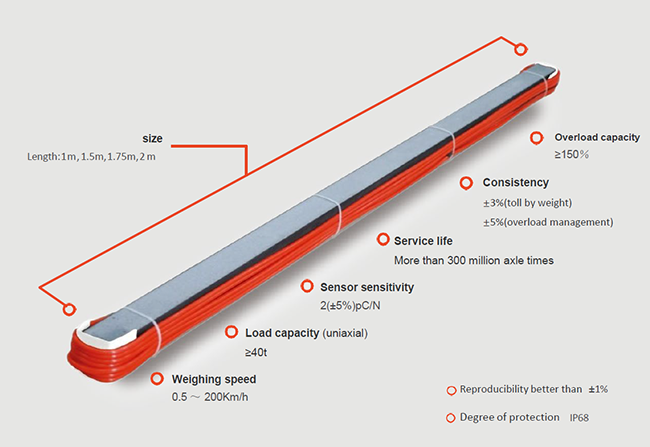

I-CET8312 yePiezoelectric Quartz Dynamic Weighing Sensor ineempawu zoluhlu lokulinganisa olubanzi, uzinzo oluhle lwexesha elide, ukuphinda-phinda okulungileyo, ukuchaneka komlinganiselo ophezulu kunye nefrequency ephezulu yokuphendula, ngoko ifaneleke ngokukodwa ukufunyaniswa kobunzima obuguquguqukayo. Yinto eqinileyo, istrip dynamic weidy sensor esekwe kumgaqo wepiezoelectric kunye nesakhiwo esinelungelo elilodwa lomenzi. Iqulunqwe nge-piezoelectric quartz crystal sheet, ipleyiti ye-electrode kunye nesixhobo esikhethekileyo sokuthwala i-beam. Ukwahlula kwiimitha ezi-1, i-1.5-meter, i-1.75-meter, i-2-meter size specs, inokudibaniswa kwiindidi ezahlukeneyo ze-sensors zendlela, ziyakwazi ukulungelelanisa iimfuno eziguquguqukayo zobunzima bomgangatho wendlela.

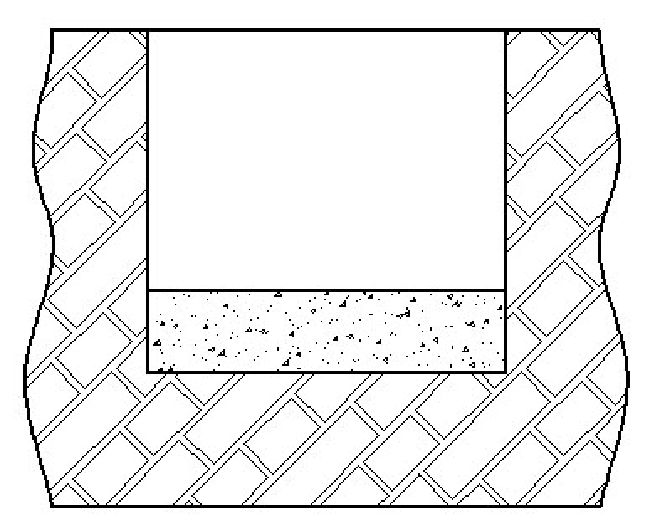

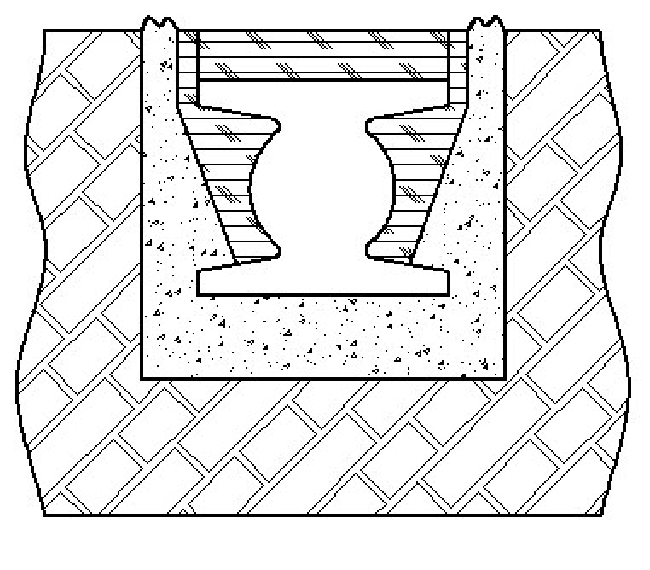

2.Umfanekiso we-CET8312

3.Iiparamitha zoBuchule

| Imilinganiselo yecandelo lomnqamlezo | (48mm+58mm)*58 mm | ||

| Ubude beSeva | 1m/ 1.5m/ 1.75m/2m | ||

| Ubude bekhebula | Ukusuka kwi-25m ukuya kwi-100m | ||

| Ubunzima be-asi (enye) | ≤40 t | ||

| Umthamo wokulayisha ngaphezulu | 150%FS | ||

| Uvakalelo lomthwalo | 2±5%pC/N | ||

| Uluhlu lwesantya | Ukusuka ku-0.5km/h ukuya kuma-200km/h | ||

| Ibakala lokhuseleko | IP68 | Ukuphazamiseka kwemveliso | >1010Ω |

| Ubushushu bokusebenza. | -45℃80℃ | Isiphumo sobushushu besiphumo | <0.04%FS/℃ |

| Uqhagamshelo lombane | Intambo ye-coaxial yengxolo ephezulu rhoqo | ||

| Ukuthwala umphezulu | Umphezulu wokuthwala unokugudiswa | ||

| Ayinamda | ≤± 2% FS (ukuchaneka kokulinganisa okumileyo kweenzwa kwindawo nganye) | ||

| Ukungqinelana | ≤± 4% FS (ukuchaneka kwe-static calibration yamanqaku eendawo ezahlukeneyo zenzwa) | ||

| Ukuphindaphinda | ≤± 2% FS (ukuchaneka kwe-static calibration yeenzwa kwindawo enye) | ||

| Unyamezelo oluchanekileyo oludityanisiweyo | ≤±5% | ||

4.Indlela yokuFakela

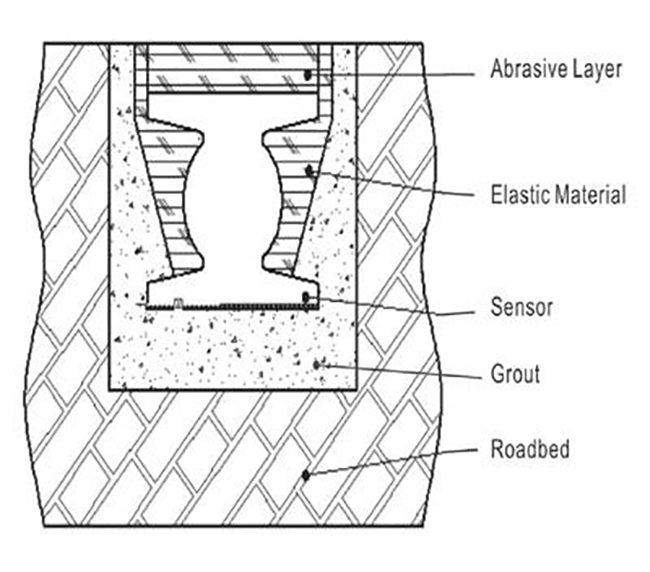

1) Ulwakhiwo lulonke

Ukuze kuqinisekiswe umphumo wokuvavanya ukufakwa okupheleleyo kwenzwa, ukhetho lwesayithi kufuneka lube ngqongqo. Kucetyiswa ukuba isamente eqinileyo

indlela yabahambi ngeenyawo kufuneka ikhethwe njengesiseko sofakelo loluvo, kwaye ipavumente eguquguqukayo njenge asphalt kufuneka iguqulwe. Ngaphandle koko, ukuchaneka komlinganiselo okanye ubomi benkonzo yenzwa bunokuchaphazeleka.

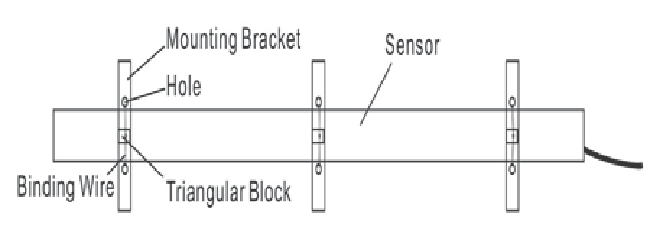

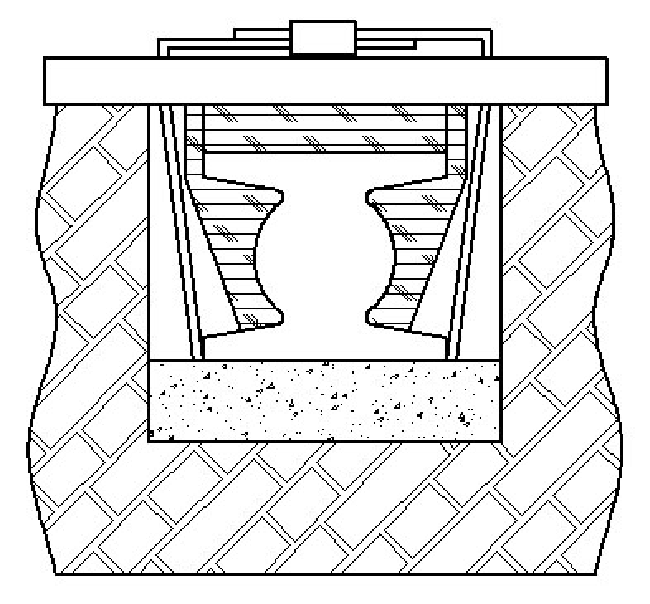

2)Isibiyeli sokuFaka

Emva kokuba indawo inqunywe, isibiyeli esixhomileyo esinemingxuma enikezelwa ngeenzwa kufuneka sigxininiswe kwi-sensor kunye ne-tape tie-wire tape ende, kwaye emva koko unxantathu omncinci wokhuni usetyenziselwa ukuxhuma kwi-gap phakathi kwebhanti yokubopha kunye ne-bracket yokufaka, ukwenzela ukuba inokuqiniswa. Ukuba abasebenzi banele, inyathelo (2) kunye (3) linokwenziwa ngaxeshanye. Njengoko kubonisiwe ngasentla.

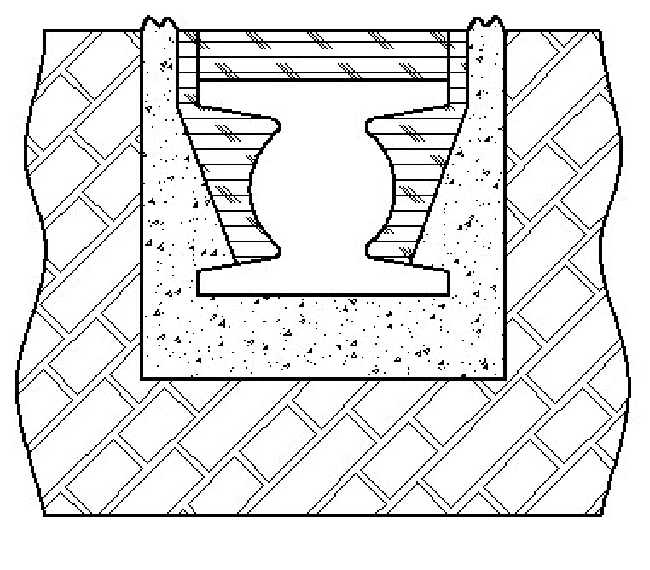

3)I-Pavement Grooving

Sebenzisa irula okanye esinye isixhobo ukumisela indawo yokunyuka yesixhobo soluvo esiguqukayo. Umatshini wokusika usetyenziselwa ukuvula iigrooves ezixande endleleni.

Ukuba i-grooves ayilingani kwaye inamaqhuma amancinci emacaleni e-grooves, ububanzi be-grooves bungama-20 mm ngaphezu kwe-sensor, ubunzulu be-grooves bu-20 mm ngaphezu kwe-sensor, kunye ne-50 mm ubude kunobunzwa. I-Cable groove yi-10 mm ububanzi, i-50 mm ubunzulu;

Ukuba i-grooves yenziwe ngokucokisekileyo kwaye imida yee-grooves ilula, ububanzi bee-grooves buyi-5-10mm ngaphezu kwe-sensors, ubunzulu be-grooves bu-5-10mm ngaphezu kwe-sensors, kwaye ubude bee-grooves buyi-20-50mm ngaphezu kweenzwa. Ingca yekhebula yi-10 mm ububanzi, i-50 mm ubunzulu.

I-bottom iya kucutshungulwa, i-silt kunye namanzi kwi-grooves iya kuphephethwa icocekile ngepompo yomoya (ukuba yomiswe ngokucokisekileyo ukuze igcwalise i-grout), kunye nomgangatho ophezulu wamacala omabini e-grooves uya kuhlonyelwa nge-tape.

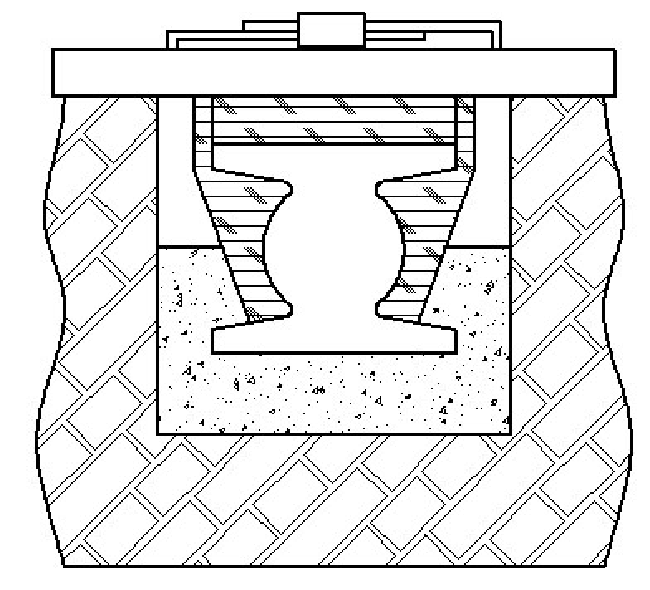

4)Ixesha Lokuqala Lokugrumba

Vula i-grout yokufakela, ngokomlinganiselo omiselweyo ukulungiselela i-grout edibeneyo, ngokukhawuleza udibanise i-grout kunye nezixhobo, uze uthele ngokulinganayo.

ulwalathiso lobude be-groove, ukuzaliswa kokuqala kwi-groove kufuneka kube ngaphantsi kwe-1/3 yobunzulu be-groove.

5)Ukubekwa kwenzwa

Beka ngobunono inzwa kunye nesibiyeli sokunyuka kwi-slot egcwele i-grout, lungisa i-bracket yokukhwela kwaye wenze i-fulcrum nganye ithinte indawo ephezulu ye-slot, kwaye uqinisekise ukuba i-sensor iphakathi kwendawo. Xa izinzwa ezimbini okanye ngaphezulu zifakwe kwi-slot efanayo, ingqalelo ekhethekileyo kufuneka ihlawulwe kwindawo yokudibanisa.

Umphezulu ophezulu wee-sensor ezimbini kufuneka ube kumgangatho ofanayo othe tye, kwaye ukudibanisa kuya kuba yinto encinci kunokwenzeka, ngaphandle koko impazamo yokulinganisa iya kubangelwa. Gcina ixesha elininzi ngangokunokwenzeka kwisinyathelo (4) kunye (5), okanye i-grout iya kunyanga (i-1-2 iiyure zexesha eliqhelekileyo lokunyanga iglue yethu).

I-6) Ukususwa kwe-Bracket yokuHlala kunye ne-Second Grouting

Emva kokuba i-grout iphiliswe ngokusisiseko, jonga umphumo wokuqala wofakelo lwenzwa, kwaye uyilungise ngexesha elifanelekileyo ukuba kuyimfuneko. Yonke into ilungile ngokusisiseko, emva koko susa isibiyeli, qhubeka ne-grouting yesibini. Eli naliti lilinganiselwe kumphakamo womphezulu wenzwa.

7) Ixesha lesithathu Grouting

Ngethuba lokunyanga, qaphela ukwandisa inani le-grout nangaliphi na ixesha, ukwenzela ukuba inqanaba elipheleleyo le-grout emva kokuzaliswa liphezulu kancinci kunomgangatho wendlela.

8)Ukugaya umphezulu

Emva kokuba yonke i-grout yokufakela ifikelele kumandla okuphilisa, krazula i-tape, kwaye ugaye i-groove surface kunye nomgangatho wendlela, ukuqhuba uvavanyo lokulayishwa kwangaphambili kunye nesithuthi esiqhelekileyo okanye ezinye izithuthi ukujonga ukuba ukufakwa kwenzwa kulungile.

Ukuba uvavanyo lokulayishwa kwangaphambili luqhelekile, ukufakela

igqityiwe.

5.Izaziso zoFakelo

1) Akuvumelekanga ngokungqongqo ukusebenzisa inzwa ngaphaya koluhlu kunye nobushushu bokusebenza ixesha elide.

2) Akuvumelekanga ngokungqongqo ukulinganisa ukunyanzeliswa kwe-sensor kunye nemitha ephezulu yokumelana ne-1000V.

I-3) Abasebenzi abangengabo abachwephesha banqatshelwe ngokungqongqo ukuba bayiqinisekise.

4) Umlinganiselo wokulinganisa kufuneka uhambelane nezinto ze-aluminium, ngaphandle koko imiyalelo ekhethekileyo iyafuneka xa iyala.

I-5) Ukuphela kwemveliso ye-sensor L5 / Q9 kufuneka igcinwe yomile kwaye icocekile ngexesha lokulinganisa, ngaphandle koko ukukhutshwa kwesignali akuzinzile.

I-6) I-pressure surface ye-sensor ayiyi kubethwa ngesixhobo esinqabileyo okanye amandla anzima.

7) I-bandwidth ye-amplifier yentlawulo iya kuba phezulu kuneyenzwa, ngaphandle kokuba akukho mfuneko ekhethekileyo yokuphendula rhoqo.

I-8) Ukufakwa kwee-sensor kufuneka kuqhutywe ngokungqongqo ngokuhambelana neemfuno ezifanelekileyo zemiyalelo ukuze kuphunyezwe umlinganiselo ochanekileyo.

6.Izihlomelo

Incwadi ye-1 PCS

Ukufaneleka kokuqinisekiswa 1 PCS Certificate 1 PCS

IHangtag 1 PCS

Intambo yemveliso ye-Q9 1 PCS

Enviko Technology Co.,Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

I-Ofisi yaseChengdu: iNombolo ye-2004, iYunithi 1, iSakhiwo sesi-2, iNombolo ye-158, i-Tianfu 4th Street, i-Hi-tech Zone, i-Chengdu

Hong Kong Office: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Ixesha lokuposa: Aug-19-2024